Do Porcelain Tiles Require Sealing?

14-June-22

Do Porcelain Tiles Require Sealing?

Porcelain as we understand it is created from a more purified combination of high-quality clay that has been used in as compared to that in "regular" ceramic production, with china or porcelain clays predominating. These contain a high silica concentration and produce materials with all of the properties of silica once burned, such as minimal moisture absorption, excellent corrosion resistance, high damage tolerance, and great overall toughness. But the burning question is do porcelain tiles require sealing? Let us take you a detailed answer to this.

The developers of this technique recognized its excellent result and promoted it appropriately, with porcelain serving as the standard. Permeability was one of the most visible technical aspects employed by manufacturers to promote this high-performance attribute.

Water absorption is limited to less than 0.5 percent according to European regulations. Many producers exceeded this excellent threshold, with ordinary moisture absorption of less than 0.1 percent. So, because the clay is crushed and sprayed dry to such tiny particle sizes prior to pressing and burning at over 1200 degrees Celsius, the resultant porcelain does not require sealing.

As a result, it should be the conclusion of the narrative. Nevertheless, this is not the case. There really are currently various varieties of porcelain, particularly glossy porcelain tiles that retain fluids and thus benefited from the sealant.

Which Porcelain Tiles Require Sealing?

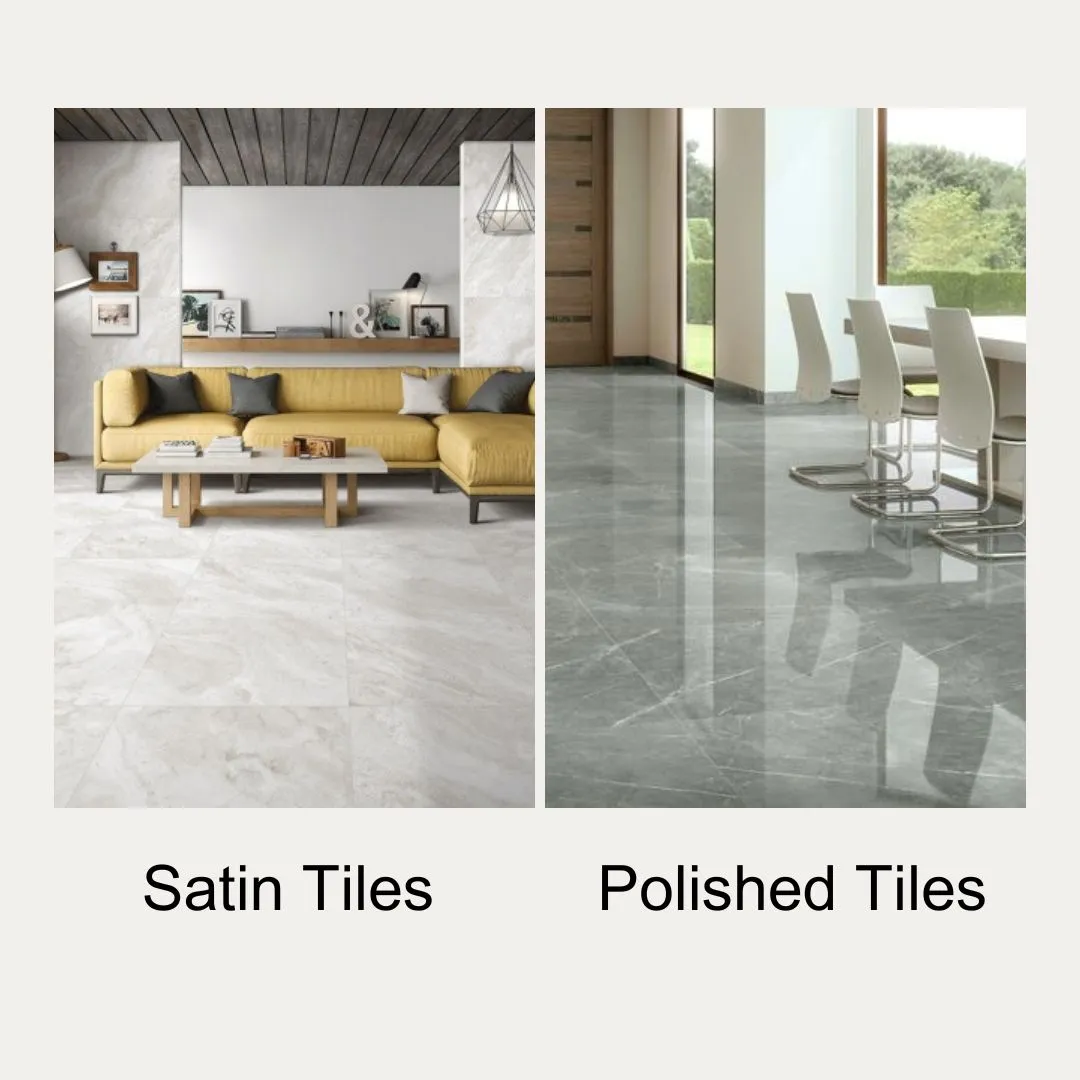

Tiles are classified into two types: those having a glossy or coated finish, and untreated or matte finish. The shiny finish of a polished tile is formed during the production processes, which opens up micro-pores in the porcelain's top. So, why porcelain tiles require sealing? Because if not sealed it increases the surface's susceptibility to stains. And also causes them to be more slippery.

Certain tiles are protected throughout the production cycle, whereas some are not. The majority of polished porcelain requires a protective coating or sealant. By identifying a surplus tile/off-cut with black ink, you may do a basic test. If the pen trace can be removed with a little white spirits solution, the tile is cured so no more measures are needed. If otherwise, it is recommended to seal the tile before grouting to prevent 'phrasing' from grout remnants.

Because most polished porcelain would have had some kind of industrial wax-type seal placed on it, it's often a good idea to wash the tiles again before sealing them.

Although unpolished tiles do not require sealing, they will stand to gain from a protective coating. Some porcelain tiles are textural, and even the smallest variation may gather dust or debris — this can be especially problematic throughout placement when grout and other remnants get caught in the uneven surface.

One of the reasons why you need to seal porcelain tiles is because the particles that get stuck in the voids will detract from the appearance of the tiles, making maintenance more challenging, and may accumulate and cause a slippery surface. Outdoor porcelain tiles are especially problematic since they frequently have a finely textural surface to provide traction underneath.

Conclusion

We have made it evident from above that, though you may not require to seal porcelain tiles surfaces all the time, it is a good idea depending upon its application and type. For naturally matter and unpolished porcelain tiles you would not need sealant whereas for polished tiles you most definitely need to seal them.

Before you ask yourself the question “How to seal porcelain tiles?” Always spend some time considering the type of porcelain tiles you own or its application area, is it too prone to dirt and dust or does it require traction. Determining the need for sealing and the kind of porcelain tiles will go a long way in choosing the right sealant for you.